Qingdao-made TBM exported to the Philippines

0 Comment(s)

0 Comment(s) Print

Print E-mail China.org.cn, September 14, 2017

E-mail China.org.cn, September 14, 2017

|

|

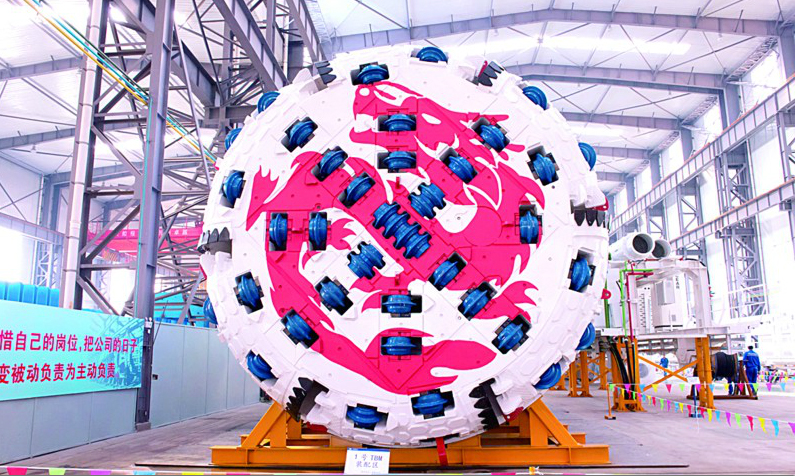

The cutterhead of "Guanlong" TBM. With the rotation of the cutterhead, the machine is able to bore through a variety of strata no matter how hard they are. It once bored 330 meters in a month in the construction of a metro line in Qingdao, ten times that of conventional blasting. |

In 2015, China’s first DSUC hardrock tunnel boring machine (TBM) was used in the construction of Qingdao’s Metro Line 2, boring a maximum of 330 meters a month, ten times that of the conventional blasting method. The use of four TBMs significantly raised the construction efficiency of the line.

On July 7, a TBM to be used for a water diversion project in the Philippines came off the production line in Qingdao, marking the first export of TBMs independently developed, designed and manufactured by China.

On July 19, the West Coast section of Qingdao’s subway line 1 introduced the use of TBM, marking the start of mechanization in the construction.

All the TMBs mentioned above were made by China Shipbuilding Industry (Qingdao) Rail Transport Equipment Co., Ltd.

So far the company has manufactured six TBMs and six earth pressure balances (EPBs). By the end of October, it will deliver eight TBMs and 12 EPBs for the construction of Qingdao’s subway line 1. The company obtained three invention patents and 10-odd utility model patents for the products.

By the end of this year, the company will achieve full proprietary IPR for the TBMs and EPBs and the localization rate for their production will increase to 80 percent.

Go to Forum >>0 Comment(s)