The State Council Information Office published on Friday a white

paper entitled The Quality and Safety of Food in China.

The document, composed of five chapters, describes the Chinese

government's efforts in enhancing the level of food quality and

improving the situation of food safety over the past years. The

full text of the white paper follows:

The Quality and Safety of Food in

China

I. Food Production and Food

Quality

II. Food Safety Regulatory System and

Work

III. Supervision of Imported and Exported

Food

IV. Law Regime and Technological Guarantee

System for Food Safety

V. International Exchanges and Cooperation

Regarding Food Safety

The quality and safety of food is a major benchmark of the

economic development and people's living conditions of a country.

Adhering to the people-oriented approach, the Chinese government

has always attached great importance to food quality and safety.

Moreover, sticking to the principle of nipping problems in the bud,

it has built and improved a supervisory system and mechanism for

food safety, strengthened legislation and the setting of relevant

standards, exercised strict quality control regarding food,

actively promoted international exchanges and cooperation in this

respect, and has greatly raised public awareness of food safety.

Thanks to such efforts, the overall level of food quality in China

is being steadily enhanced, the situation of food safety is

continuously improving, and the order in food production and

operation have markedly turned for the better.

I. Food Production and Food

Quality

1. The Quality and Safety Level of Processed Food Is

Steadily Improving

(1) Rapid and Sound Development of the Food-processing

Industry

In recent years, China's food industry has maintained fast and

sound growth, with a steady increase in economic benefits.

Foodstuffs can be classified by their raw materials and processing

techniques into 525 kinds in 28 categories: processed grain

products; edible oil, fat and fat products; seasonings; meat

products; dairy products; soft drinks; convenient food; biscuits;

canned food; iced drinks; fast-frozen food; potato and dilated

food; candies (including chocolate and chocolate products); tea;

alcoholic beverages; vegetable products; fruit products; roasted

seeds and nuts; egg products; cocoa and bakery coffee products;

sugar; processed aquatic products; starch and starch products;

pastries; bean products; bee products; special diet food, and

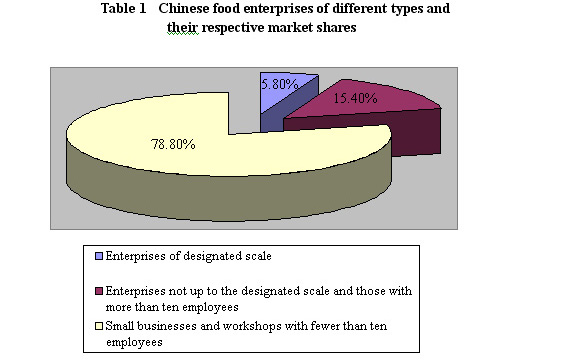

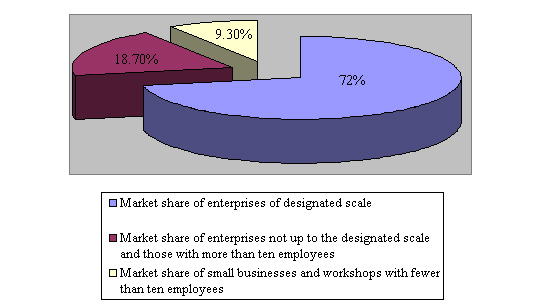

others. At present, China has 448,000 enterprises engaged in

foodstuff production and processing. Among them, 26,000 enterprises

of designated scale 1 occupy 72 percent of the market, taking the

leading role in terms of output and sales revenue; 69,000 are

enterprises not up to the designated scale and those with more than

ten employees, taking up a market share of 18.7 percent; and

353,000 are small businesses or workshops with fewer than ten

employees, with a market share of 9.3 percent. (See Table 1)

1

Refering to private industrial enterprises with annual revenue of

two million yuan or more and all state-owned industrial

enterprises, as well as private commercial enterprises with annual

revenue of five million yuan or more and all state-owned commercial

enterprises. — Tr.

|

|

Statistics show that, in 2006, industrial food enterprises of

designated scale generated 2,158.695 billion yuan of output value

(excluding tobacco), accounting for 6.8 percent of the national

industrial output value, and up 23.5 percent year on year. The

average annual industrial added value and profit of processing

enterprises of grain, oil, meat and dairy products all exceeded 20

percent. The output of major foodstuffs in 2006 were: wheat flour,

51.93 million tons; edible vegetable oil, 19.855 million tons;

fresh frozen meat, 11.125 million tons; dairy products, 14.596

million tons; beer, 35.152 million kl; and soft drinks, 42.198

million tons. These figures show rises of 28.2 percent, 17.5

percent, 24.0 percent, 23.5 percent, 14.7 percent and 21.5 percent

year on year, respectively. In the first six months of 2007, the

accumulated output value of the food industry amounted to 1,281.62

billion yuan, up 29.9 percent as compared with the corresponding

period last year. The output of beer, edible oil, soft drinks and

gourmet powder led the world.

At present, the development of China's food industry displays

the following features:

One, the processing techniques and equipment of some food

enterprises reach or approach the advanced international level.

Large meat, dairy product, beverage and beer producers all have

world first-class production and testing facilities, which

guarantees the quality of their products. The development and

application of such key processing techniques as

membrane-separation technology, physical property modification,

cold-aseptic filling, concentration and cold processing has

narrowed China's gap with the world advanced level in terms of

processing technology and equipment.

Two, quality control of the enterprises has become more

scientific and standard. So far, 107,000 food producers have

obtained market access permits regarding quality and safety, and

2,675 have been granted hazard analysis and critical control point

(HACCP) certificates.

Three, the structure of products is being improved to cater to

the increasingly diverse demands of consumers. The proportion of

intensively or deeply processed foodstuffs to the total output of

foodstuffs keeps increasing. For instance, liquid dairies now

account for more than 85 percent of the total output of dairy

products; colas no longer dominate the market, as a result of the

mushrooming of packed drinking water and fruit, vegetable and tea

drinks; special flour above second grade accounts for 65 percent of

the total output of wheat flour; standard rice above first grade

accounts for 88 percent of the total output of rice, and special

rice for 33.9 percent of the total output of rice; and Grades I and

II oil (salad oil and quality culinary oil according to previous

national standards) accounts for 58.5 percent of the total output

of edible vegetable oil.

(2) Continuous Improvement of Food Quality

One, the acceptance rate of foodstuffs on the whole is steadily

rising. The rate was 77.9 percent in the 2006 national foodstuffs

sample survey, and it rose to 85.1 percent in a similar survey in

the first half of 2007. The level of food quality and safety

remains stable, with a gradual upturn. (See Table 2)

Table 2 Acceptance rate of

foodstuffs in sample surveys from 2005 to June 2007

Two, the quality of food produced nationwide is improving. In

the first half of 2007, the 31 provinces, autonomous regions and

municipalities directly under the Central Government on the

mainland of China reported an average 89.2-percent acceptance rate

of foodstuffs, and the figure in 14 of them surpassed 90

percent.

Three, the quality of food in key sectors is fairly high. Thanks

to the country's endeavors to improve the work of food producers

and processors, the quality of 525 kinds of foodstuffs in 28

categories has been enhanced to various degrees, with remarkable

progress in the quality of food with a large daily consumption.

According to statistics, the ten foodstuffs with the largest

consumption are edible oil, fat and fat products; alcoholic

beverages; aquatic products; processed grain products; soft drinks;

meat products; dairy products; seasonings; starch and starch

products; and sugar. In the first half of 2007, sample surveys

showed a 90-percent or higher acceptance rate of all the above ten

foodstuffs except aquatic products, whose acceptance rate was 85

percent. That of meat products was 97.6 percent. (See Table 3)

Table 3 Acceptance rate of the ten

most-consumed foodstuffs in the first half of 2007

(3) Quality Food Dominating the Market

Along with the development of the food industry, the scale of

food producers keeps growing, production is becoming more

concentrated, and the quality of foodstuffs of large and

medium-sized producers is sound. In 2006, the top 100 revenue

earners held 24.9 percent of the total sales of the food industry;

the top ten dairy producers generated 54.7 percent of the total

revenue of the dairy industry; the top ten soft-drink producers

generated 39.5 percent of the total output of that industry; the

top ten sugar makers produced 43.6 percent of the total output of

the sugar industry; the top 50 meat producers accounted for 70

percent of that industry in terms of production capacity and sales;

the eight beer brewery groups, each with a production capacity of

over one million kl, produced 57 percent of the national beer

output; the ten largest wineries produced 62.1 percent of the

national output; and the three largest instant noodle producers

occupied 76 percent of the Chinese market.

2. The Quality and Safety of Agricultural Products Is

Steadily Improving

(1) Fast Growth of High-quality and Safe

Brands

Quality agricultural products are steadily expanding their

market. Agricultural standardization has been notably enhanced,

which increases farmers' income and changes their farming patterns.

Hazard-free, green and organic products make up 90 percent of all

agricultural-product exports. Over the past five years, the export

of green food has shot up 40 percent annually, and has been

accepted by over 40 of China's trading partners. So far, China has

developed 28,600 kinds of hazard-free agricultural products, and

set up 24,600 hazard-free production bases with a total area of

21.07 million hectares. Five thousand three hundred and fifteen

Chinese enterprises use the green food logo on their 14,339 kinds

of products totaling 72 million tons and grown on 10 million

hectares of land. In addition, 600 producers use the organic food

logo on their 2,647 kinds of products totaling 19.56 million tons

and grown on 3.11 million hectares of land. Altogether, there are

539 state-level agricultural demonstration zones, 100 demonstration

counties (farms) and nearly 3,500 provincial-level demonstration

zones, with a combined growing area exceeding 33.33 million

hectares.

(2) Acceptance Rate of Agricultural Products Rising

Continuously

Inspections in the first half of 2007 showed that the average

acceptance rate regarding pesticide residues in vegetables was 93.6

percent; those regarding clenbuterol hydrochloride contamination

and sulfa drug residues in livestock products was 98.8 percent and

99.0 percent respectively; and that regarding chloromycetin in

aquatic products was 99.6 percent, of nitrofuran 91.4 percent, and

of pesticide residue over 95 percent in sample surveys done at

production bases.

3. The Quality of Imported and Exported Foodstuffs Stays

High

China is a large importer and exporter of foodstuffs, with the

amount of each growing steadily in recent years. The import and

export volume in 2006 totaled US$40.448 billion-worth (excluding

wheat, corn and soybean, same below), up 21.45 percent year on

year. (See Table 4)

Table 4 China's food import and

export volumes in 2005 and 2006

(1) Safety of Export Food Guaranteed

In 2006, China exported 24.173 million tons of food, worth

US$26.659 billion, up 13.29 percent and 16.0 percent year on year,

respectively. The top ten varieties in terms of export value were

aquatic products, processed aquatic products, vegetables, canned

food, juices and drinks, processed grain products, seasonings,

poultry products, alcoholic beverages, and livestock meat and

chopped entrails. (See Table 5)

Table 5 Top ten food varieties in

terms of export value in 2006 as compared with 2005

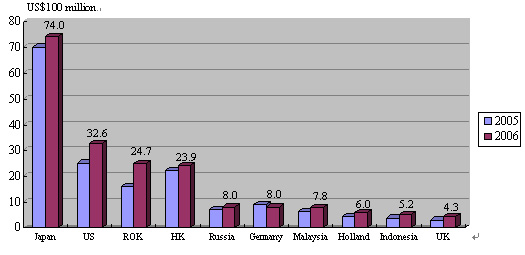

Foodstuffs of the mainland of China have been exported to more

than 200 countries and regions, of which the top ten in terms of

trade volume are Japan, the US, the ROK, Hong Kong, Russia,

Germany, Malaysia, Holland, Indonesia and the UK. (See Table 6)

Table 6 Top ten countries and

region in terms of China's export value of food in 2006 as compared

with 2005

|

For many years, over 99 percent of China's exported foodstuffs

have been up to standard. In 2006 and the first half of 2007, China

exported to the US some 94,000 batches and 55,000 batches of

foodstuffs, respectively, and 752 batches and 477 batches of each

were found by the US to be substandard, making the acceptance rate

99.2 percent and 99.1 percent, respectively. In the case of the EU,

the figures were 91,000 batches and 62,000 batches, with 91 batches

and 135 batches found by the EU to be substandard, making the

acceptance rate 99.9 percent and 99.8 percent, respectively. On

July 20, 2007, the Ministry of Health, Labor and Welfare of Japan,

the largest importer of Chinese food, released an examination

report on food imported from China in 2006, which showed that Japan

conducted more sample surveys on Chinese food (15.7 percent) than

on food from anywhere else, but Chinese food had the highest

acceptance rate (99.42 percent), followed by that imported from the

EU (99.38 percent) and the US (98.69 percent). The mainland of

China is a major supplier of food for the Hong Kong Special

Administrative Region. Two large food sample surveys conducted by

Hong Kong's Food and Environmental Hygiene Department in the first

half of 2007 showed that the acceptance rate stood at 99.2 percent

and 99.6 percent, respectively.

(2) Quality of Imported Food Stable

In 2006, China imported 20.273 million tons of food, worth

US$13.396 billion, up 37.94 percent and 25.11 percent year on year,

respectively. The top ten varieties in terms of import value were

vegetable oil, aquatic products, cereals, sugar, dairy products,

alcoholic beverages, tobacco and associated products, poultry and

chopped entrails, oil crops, and processed grain products. (See

Table 7)

Table 7 Top ten food varieties in

terms of import value in 2006 as compared with 2005

China imports foodstuffs from 143 countries and regions, and the

top ten in terms of trade value are Malaysia, Russia, the US,

Indonesia, Argentina, Thailand, Australia, New Zealand, Brazil and

France. (See Table 8)

Table 8 Top ten countries in terms

of China's import value of food in 2006 as compared with

2005

For many years, the quality of food China imports has been

fairly stable, and no serious hazard has been caused by imported

food. During the period from 2004 to the first half of 2007, the

acceptance rate of imported food, according to statistics released

by the ports of entry, were 99.29 percent (2004), 99.46 percent

(2005), 99.11 percent (2006) and 99.29 percent (first half of

2007), respectively.

II. Food Safety Regulatory System and

Work

To ensure food safety, the Chinese government adheres to the

principle of giving priority to prevention and control at its root

by monitoring and controlling the whole process, and has formed a

regulatory format in which the local governments take the

responsibility, related departments provide guidance and conduct

coordination, and different sectors make concerted efforts under

the unified national leadership. In response to the circumstances

in China, the State Council issued the Decision on Further

Strengthening Food Safety Supervision in 2004, according to which

one monitoring link is supervised by one department; sectional

supervision is adopted as the main means while supervision of

different varieties as the supplementary means, making clearer the

functions and responsibilities of the food safety supervisory

departments. The Decision divided food safety supervision into four

links, managed by the departments of agriculture, quality

supervision and inspection, industry and commerce, and health,

respectively. The production of primary agricultural products is

supervised by the agriculture department, the quality and daily

hygiene supervision of food processing is overseen by the quality

supervision and inspection department, supervision of food

circulation and distribution is done by the department of industry

and commerce, and that of the catering industry and canteens is

taken care of by the health department. The integrated food-safety

supervision and coordination, and investigation of and penalties

imposed for major incidents in this regard are the responsibility

of the department of food and drug administration, while imported

and exported agricultural products and other foodstuffs are

supervised by the quality supervision and inspection department. In

this way, there is a strict, complete regulatory system for food

safety supervision in which the departments concerned work in close

cooperation, with clearly defined functions and

responsibilities.

As it is a prolonged and arduous task to strengthen food safety

control, a regulatory system and a lasting efficiency mechanism

should be established and improved, and planned with consideration

given to both present and future needs to deal with both the

symptoms and root causes of food safety problems, especially the

latter.

The Chinese government stresses food safety from the source,

improvement of the related basic regulatory systems, and

strengthening of food safety supervision.

1. Intensifying Supervision on the Quality and Safety of

Agricultural Products

In 2001, China started to implement the Hazard-free Food Action

Plan, focusing on the control of residue of high-toxic pesticides

in vegetables and clenbuterol hydrochloride contamination in

livestock products, to address the most concerned problems of

illegal use of high-toxic pesticide and veterinary medicines, as

well as violations of residue standards. The Plan stipulates a

complete supervisory process from farmland to market by emphasizing

the three key aspects of materials used in farming, production and

market excess. By carrying out regular monitoring and inspection,

the Plan aims at enhancing people's awareness of food quality and

safety, ensuring management responsibility, and improving the

levels of management and quality and safety of agricultural

products by means of standardization. Today, the system for

securing the quality and safety of agricultural products is

improving, with steadily strengthened supervisory capacity and

notable progress in agricultural standardization, leading to the

formation of a work mechanism integrating service, management,

supervision, penalty and emergency response, to ensure the quality

and safety of agricultural products.

2. Establishing and Strictly Implementing Market Access

Systems for Food Quality and Safety

The food quality and safety market access systems established by

the Chinese government in 2001 comprise three major ones. One, the

production license system, which requires that food-processing

enterprises cannot produce and market their products without having

the capability to control the source materials' quality, and the

adequate conditions to ensure food quality and safety in terms of

production equipment, technological flow, product standardization,

testing equipment and capability, environment, quality control,

storage and transportation, packaging and labeling, and production

staff. Enterprises can produce and sell food only after obtaining a

food production license. Two, the compulsory inspection system,

which means that enterprises have the legal obligation to ensure

that their food products pass quality inspection before entering

the market. Three, the market access labeling system, i.e.,

enterprises are required to put on food products the QS label,

guaranteeing their quality and safety. Following the principle of

phased implementation, by the end of June 2007, some 107,000 food

production licenses had been issued to enterprises, which took up

over 90 percent of the market of their trades. Meanwhile,

supervision has been strengthened over enterprises with food

production licenses. By the end of June 2007, 1,276 food production

licenses had been withdrawn, cancelled, revoked or nullified for

substandard food products. In pace with the growing number of

enterprises obtaining the license, the General Administration of

Quality Supervision, Inspection and Quarantine has released lists

of such enterprises, making clear that producers without the

license and products without the QS label must not enter the

market, and warning consumers not to use such products.

3. Intensifying State Supervision by Sample Survey for

Food Quality

The Chinese government carries out a food supervision and

inspection system mainly by means of sample survey. Since it was

set up in 1985, the system has been strengthened and become more

focused to enhance its efficiency. In recent years,

daily-consumption food items, such as dairy products, meat

products, tea, beverages, grain and edible oil, have become the

major targets of sample surveys, especially those produced in

workshops and enterprises located in concentrated food-producing

areas. Special attention has been given to the hygienic indices of

microorganisms, additives and heavy metals in food, and to

follow-up inspections of small enterprises with unstable product

quality. By increasing sample survey frequency and coverage, the

goal of rectifying producers of the same type of food by means of

sample survey has been by and large met. The state supervisory

sample surveys were carried out on 11,104 batches of foodstuffs

produced by 7,880 enterprises from 2006 to June 2007. Meanwhile,

greater efforts have been made to rectify and punish enterprises

turning out substandard products, and to set things straight by

means of the following: First, strictly implementing the public

announcement system. Three hundred and fifty-five batches of food

with serious quality problems produced by 355 enterprises were

found in sample surveys and publicly announced. At the same time,

publicity is given to good enterprises, quality products and sound

brands. Two hundred and forty products winning the title of "Famous

Chinese Brand" and 548 freed-from-inspection products have become

popular among consumers. Second, strictly carrying out the

rectification system. Enterprises with substandard products are

urged to rectify themselves strictly, to be examined again in due

course. If problems persist, they will be ordered to stop

production for an overhaul. If they still cannot pass the

inspection after the overhaul, their business licenses will be

revoked. Third, strictly implementing the penalty system. Producers

who mix impurities or imitations with their products, or pass fake

or defective products off as genuine ones will be ordered to stop

production, and their products be confiscated. Legal liabilities

will be imposed in serious cases by the judicial organs.

4. Intensifying Rectification of Food

Workshops

Regional differences and disparities between urban and rural

areas in China make the supervision of food workshops a prolonged

and arduous task. At present, food workshops with fewer than ten

employees are the ones that pose the most difficult problem for

ensuring food quality and safety. For workshops engaged in

traditional, low-risk food processing, the government sticks to the

principle of supervision and standardization while giving guidance

to such workshops for consumers' convenience. On the one hand, the

government has tried to upgrade them to the market-access

requirements by means of shutdown, stoppage of production, merging

or changing line of business; on the other, more stringent

supervisory measures have been taken to prevent food safety

accidents. In recent years, supervision of workshops and small

enterprises has been conducted mainly in four aspects: One,

transformation of basic work conditions. Workshops cannot start

production without meeting the requirements. Two, restrictions on

market scope. Food products processed by such small workshops are

not allowed to sell outside the administrative areas of townships

or towns in which they are located, not allowed to enter shopping

centers and supermarkets. Three, restrictions on food packaging.

Before obtaining a market access permit, food products from the

workshops are not allowed to have marketing package, so that they

cannot enter the market disguised as licensed goods. Four, public

undertaking. Food workshops must undertake to the public that they

do not use any non-food materials, misuse additives, use recycled

food, send their products to shopping centers or supermarkets, or

market their products beyond the approved region, and guarantee

that their food products meet the basic safety and hygienic

standards. After such rectifications, the average acceptance rate

in sample surveys of food workshops rose to 70.4 percent in 2006.

By the end of June 2007, 5,631 workshops had been closed down,

8,814 had been made to suspend production, and 5,385 had reached

the requirements after rectification.

5. Promoting the Responsibility System for Regional Food

Safety Control

The responsibility system for regional food safety control

mainly comprises the following aspects. First, to have specified

persons responsible for specified regions and enterprises. The

system requires that food safety inspectors of the quality

supervision and inspection department go to the townships to

supervise the food-processing enterprises; township government

coordinators assist the inspectors in supervising food quality and

safety; and local reporters bring to attention anything illegal

regarding food quality and safety. The number of inspectors,

coordinators and local reporters must be fixed, their duties

defined, and their working areas and inspecting enterprises

designated. Second, the system requires "three enters" and "four

graphs." The former refers to entering villages, households and

enterprises to find out their working conditions and set up files

of food producers and processors; the latter refers to drawing up a

graph showing dynamic changes in enterprises, a graph showing the

distribution of food producers and processors, a graph showing the

implementation of supervisory duties, and a graph giving food

safety precautions, so as to carry out proactive monitoring and

control. Third, the system requires local governments to sign

documents of responsibility, enterprises to sign letters of

undertaking, and quality supervision and inspection departments to

submit regular food safety reports.

By the end of June 2007, a total of 16,030 food-safety

supervision regions had been set up, 25,346 full-time food-safety

inspectors had been put to work, 72,474 local government

coordinators had been appointed, and 106,573 food-safety reporters

had been recruited in 31 provinces, autonomous regions and

municipalities directly under the Central Government. In 2006, the

quality supervision and inspection departments at various levels

made 900,000 inspections of food producing and processing

enterprises.

6. Stepping up Supervision of the Food Circulation

Sector

The "Three Green Projects" have been vigorously promoted in

China, advocating "green consumption, green markets and green

channels." The government encourages modern modes of organization

and management for circulation, positively supports the development

of chain management and logistics provision; urges marketing

enterprises to examine materials before accepting them, check

business licenses, require invoices for purchases, keep accounts of

transactions and honor their undertakings for food quality, as well

as promotes market managers' food quality responsibility system;

implements market inspection system in an all-around way; improves

the food quality monitoring system, and strictly implements the

system that substandard food must be withdrawn from the market and

destroyed and made known to the public; strengthens administration

over butchering of livestock and fowls, breaks down regional

barriers and encourages the nationwide circulation of high-quality

foodstuffs with good credit standing and prestigious brand names;

improves food processing, circulation and service systems in

communities; strengthens the management of the use of genuine food

safety labels and standard packaging, and concentrates efforts to

crack down on printing of fake packaging, labels and

trademarks.

7. Intensifying Supervision of Food Safety in Catering

Industry

Hygiene in the catering industry is vital for food safety. In

this regard, the Chinese government has primarily done the

following: One, it has intensified supervision on hygiene in the

catering industry, promulgated and put into effect the Hygienic

Standards for the Catering Industry and Group Food Service

Providers, adopted a quantified and classified supervisory system

for food hygiene management, and strengthened supervision on each

link of the catering industry. Two, it has urged the catering

industry and canteens to implement the quantified and classified

supervisory system for food hygiene management in an all-around

way, improved and strengthened monitoring of food contamination and

building of a monitoring system on diseases caused by contaminated

food. Three, it has intensified crackdown on activities in

violation of food safety law, investigated and dealt with serious

cases and timely made them known to the public. In 2006, the health

departments inspected 2.04 million catering entities of various

types and school canteens, dealt with 45,000 cases of illegal food

processing and sale and closed down 25,000 food processors and

sellers that had been operating without hygiene permits. Four, it

has strengthened efforts on hygienic work in schools, directed and

carried out special inspections on food and drinking water hygiene,

and prevention and treatment of contagious diseases in schools all

over the country, as well as prevention of food poisoning and the

spread of communicable intestinal diseases. Five, it has conducted

food-related jeopardy assessment and issued early warnings for food

safety problems on a scientific basis and provided food assessment

information.

8. Carrying out Rectification in Respect of Food Quality

and Safety in an All-around Way

In order to crack down on the spread of counterfeit and shoddy

foodstuffs in certain regions, special comprehensive rectification

campaigns were launched in these regions for food quality and

safety. The Chinese government has conducted a special project

involving hundreds of regions, thousands of townships and tens of

thousands of food producers and processors. Targeting key regions,

food processing venues and households and their products, the

project has resolved the regional problem of producing and selling

fake and inferior goods by establishing a food safety monitoring

network, stepping up efforts in building up the technological

forces such as standardization and monitoring technology, improving

technical services for enterprises, promoting the setting up of

food industry associations, and intensifying law enforcement and

making more stringent efforts to crack down on the production and

sale of counterfeit and faulty food. Meanwhile, the departments of

industry and commerce as well as quality supervision and inspection

keep intensifying law enforcement and, with focus on food quality

and safety, direct and conduct special law enforcement actions

against activities in producing and processing counterfeit

food-related items at the source, strictly crack down on illegal

activities such as production of food with non-food materials and

misuse of additives in food, as well as food producers with neither

a business license nor food-processing permit. In 2006, the quality

supervision and inspection departments handled 49,000 illegal

operations in this field, confiscating counterfeit and shoddy

foodstuffs worth 450 million yuan. In the same year, the

departments of industry and commerce sent 5.6 million person/times

for law enforcement and inspected 16,000 key food markets and 10.4

million food operating business/times, closed down 151,800

unlicensed businesses, revoked 4,629 business licenses,

investigated and dealt with 68,000 cases of production and sale of

counterfeit and shoddy food, of which 48 cases were referred to the

relevant judicial organs, and ordered 15,500 tons of substandard

foodstuffs off the market.

9. Beefing up the Construction of a Risk-warning and

Emergency-response System

The Chinese government has established a nationwide quick risk

warning and responding system in respect of food safety, actively

conducted risk monitoring and control in food production,

processing, circulation and consumption, and preliminarily realized

the early discovery, early warning, early control and early

treatment of food-safety problems through efficient collection and

analysis of information on food safety. It has also established a

rapid and efficient response mechanism covering the collection and

analysis of risk-related information, issuing warnings and rapid

responses so that it is possible to provide prompt reports, take

swift action, make accurate judgment and mete out appropriate

measures.

10. Establishing and Improving a Food Recall

System

This system comprises two aspects: active recall and instructed

recall. The system stipulates that it is the responsibility of food

producing and processing enterprises to recall their products if

necessary, requires that food producers should instantly put a halt

to the production and selling of their products if they suspect any

safety risk in their food products, and take the initiative to

recall such food products. Producers who purposely conceal food

hazards or do not perform their recall obligations, or whose faulty

production has extended such hazards or made them recur, will be

instructed to recall their products. In recent years, in conducting

food sample surveys and law enforcement, the General Administration

of Quality Supervision, Inspection and Quarantine has become more

stringent in demanding food recall when major food-safety hazards,

such as pathogenic bacteria, chemical pollutant or non-food

materials, are found in food products. Toward those food producing

enterprises causing serious consequences, the Administration has

revoked their licenses, thus reducing hazards that might be caused

by unsafe food and safeguarding the health and safety of

consumers.

11. Improving the Food Safety Credit System

The Chinese government pays great attention to the construction

of the credit system for food safety, and has set up the

preliminary credit records for food-producing enterprises, as well

as a system to publicize the honor rolls and blacklists of food

producers and processors. Meanwhile, the functions of chambers of

commerce and trade associations have been brought into full play to

promote self-discipline in the food industry. By giving backing to

excellent and competent enterprises, the government supports and

helps good and strong enterprises by legislative, administrative

and economic means to create an honest environment for food safety,

and to enhance people's awareness of honesty in this regard. It has

made great efforts in gradual improvement of this mechanism for

food safety, and given full scope to its role in regulating,

guiding and supervising food safety. It has built up files of

credit records of food safety and promoted classified credit

monitoring in the food industry. Emphasis is laid on the

establishment of a registration and information system and a

classified database of credit records of food producers and

sellers, which collects information on food producers' and sellers'

market access, food-safety control, and consumers' complaints and

reports, to ensure an effective control based on adequate

information. In recent years, the latest network technology has

been used for this purpose, so that consumers may timely, easily,

quickly and effectively distinguish counterfeits from genuine ones,

which greatly helps safeguard consumers' interests, discourages the

production and sale of fake foodstuffs and promotes honesty among

enterprises in this industry.

Over the years, the continuous growth of the food industry in

terms of variety and quantity as well as the improvement of quality

have helped satisfy the people's ever-increasing consumption

demands, raised their living standard and promoted national

economic development. However, the Chinese government is well aware

that there are still problems with food safety, owing to the

country's limited socio-economic development. In the days to come,

penalties will be focused on those who produce shoddy products or

products containing inferior materials or impurities, palm off

counterfeits as genuine ones, process foodstuff with non-food or

moldy materials, produce foodstuff in disregard of required

standards and misuse additives in foodstuff, so as to continuously

guarantee food safety and quality.

III. Supervision of Imported and

Exported Food

1. Supervision of Imported Food

Exploration and practice over the years have enabled China to

set up a complete framework of food quality and safety supervisory

system and guarantee measures to ensure the safety of imported

food.

-- Scientific risk management system. According to the WTO

Agreement on the Application of Sanitary and Phytosanitary Measures

(SPS) and common international practice, the Chinese government

adopts an inspection and quarantine entry system based on risk

management for high-risk imported food, such as meat and vegetable,

which includes: making a risk analysis on the high-risk food that

the exporting country applies to export to China; signing an

inspection and quarantine agreement with the exporting country on

food involving acceptable risks; carrying out hygiene registration

for foreign food enterprises; and quarantining, examining and

approving the imported food of animal and plant origin. If epidemic

animal or plant diseases or severe food safety problems occur in

the exporting country, China shall take timely risk management

measures, including suspending food imports from that country.

-- Strict inspection and quarantine system. When imported food

arrives at the port of entry, the entry-exit inspection and

quarantine authorities carry out inspection and quarantine in

accordance with law, and approve the foodstuffs to be imported only

if they meet the required standards; and the customs house clears

the imported food upon the strength of the Customs Clearance List

of Inward/Outward Goods as issued by the entry-exit inspection and

quarantine authorities. Only then can the food be sold in the

Chinese market. If safety or hygienic problems are found in the

food when inspected and quarantined, corresponding measures are

immediately taken. In 2006, Chinese entry-exit inspection and

quarantine authorities altogether found 2,458 batches of foodstuffs

not meeting the standards at ports of entry. In the first half of

2007, some 896 were found, which were returned, destroyed or used

in other ways according to law. Thus is the safety of food imported

for the Chinese market assured.

-- Complete quality and safety supervisory system. While

carrying out inspection and quarantine in accordance with law, the

entry-exit inspection and quarantine authorities pay special

attention to higher-risk food and problematic foodstuffs as found

in the inspection and quarantine at the ports of entry. The

authorities promptly issue early warnings of risks when finding

imported food with serious problems or the same type of imported

food with repeated problems, and take such measures as increasing

the proportion of sample survey, adding more items for inspection,

and suspending import.

-- Strict system against illegal import. The General

Administration of Quality Supervision, Inspection and Quarantine

and the General Administration of Customs have set up a cooperation

mechanism to jointly fight illegal food imports. In 2006, China

signed with the European Union Commission the Arrangement for

Cooperation on Joint Prevention of Illegal Actions in the Import

and Export of Food, making it clear that the two sides will crack

down on such illegal activities as deception, undeclared carrying,

illegal transit and smuggling through exchanges of information,

technological cooperation, mutual visits of experts and special

joint actions. In 2006 and the first half of 2007, 12,292 tons of

illegally imported meat were seized.

2. Supervision of Exported Food

Following the principle of "prevention first, supervision at the

source, and control throughout the process," the Chinese government

has set up and improved an export-food safety management framework

composed of "one pattern and ten systems."

"One pattern" refers to the managerial pattern for the

production of export food -- "enterprise + base + standardization."

This pattern conforms to China's reality and the actual situation

in the field of export food, and thus is an important guarantee for

the quality of such food. Besides, it is the only way for

enterprises to aim for scale and intensive development in the

international market. With unremitting efforts over many years,

China has basically put this pattern in place for major export food

items, especially high-risk foodstuffs such as meat, aquatic

products and vegetable.

The "ten systems" are: three for supervision at the source --

the archiving management system for the inspection and quarantine

of planting and breeding bases, the epidemic disease monitoring

system, and the supervisory system for pesticide and veterinary

medicine residue; three for factory supervision -- the hygiene

registration system, the classified management system for

enterprises, and the resident quarantine official system for large

enterprises producing high-risk food for export; three for product

supervision -- the legal inspection and quarantine system for

export food, the system of quality tracing and substandard products

recalling, and the early risk warning and quick response system;

and one for credit building -- a red list and a blacklist for food

export enterprises.

-- Strengthening supervision of planting and breeding at the

source. To effectively control the risks of animal epidemics, plant

diseases and pesticide and veterinary medicine residue, and

guarantee food quality and safety and traceability at the source,

the entry-exit inspection and quarantine authorities adopt the

archiving management system for the inspection and quarantine of

export food material bases with such risks. Only the raw materials

of planting and breeding bases with archiving approval can be used

in processed export food, and all the raw material bases with

archiving approval are publicized on the website of the General

Administration of Quality Supervision, Inspection and Quarantine.

So far, 6,031 breeding farms and 380,000 hectares of planting bases

have obtained such approval. For these bases, the relevant agencies

strengthen supervision, prevention and control of epidemic

diseases, exercise tight management of agricultural input

materials, and enforce a strict supervision system over pesticide

and veterinary medicine residue, so that these problems are brought

under effective control. In recent years, bird flu has been found

in many places around the world, but none at the bases under

archiving management in China.

-- Strengthening supervision of food producing enterprises.

China has adopted a hygiene registration system for all enterprises

producing export food, and an enterprise has to be granted such

registration before engaging in the production of export food. So

far, 12,714 enterprises have been registered, among which 3,698

have passed the HACCP certification of the entry-exit inspection

and quarantine authorities. The local entry-exit inspection and

quarantine authorities carry out routine supervision and

administration of the registered food producing and processing

enterprises in a unified way to ensure that the raw materials come

from archived planting and breeding bases, and that the production

and processing meet the required standards. As regards large

enterprises producing or processing high-risk export food such as

meat, the entry-exit inspection and quarantine authorities send

resident officials to supervise them when needed. The packaging of

export food should be labeled with traceable signs according to

requirements, so as to ensure the traceability of the products and

recall of substandard products.

-- Strengthening inspection and quarantine before the food is

exported. As prescribed by Chinese laws, all food should meet the

standards set by the inspection and quarantine authorities before

being exported, and the customs houses at the ports of exit should

clear the export food upon the strength of the Customs Clearance

List of Outward Goods issued by the entry-exit inspection and

quarantine authorities. If it is demanded by the importing country,

the relevant entry-exit inspection and quarantine authorities

should issue a hygiene certificate to prove that the food meets the

required standards, and enter on the certificate the name, address,

number of hygiene registration of the producing enterprise, date of

production, date of export, loading port and destination port. When

the goods arrive at the port of exit, the inspection and quarantine

authorities at the port should examine the goods again, making sure

they are intact and conform to the information on the certificate.

All these measures guarantee the traceability of the food.

-- Strengthening the construction of the export enterprise

credit system. An export enterprise quality undertaking system and

a red list and blacklist system for export enterprises are

implemented in a comprehensive way, and efforts are being made to

increase the awareness of the persons primarily responsible for

product quality and help enterprises to form a mechanism of

self-management, self-discipline and consciousness of operation in

good faith. Included on the List of Sound Enterprises are those

with a complete and effective control system, good faith, effective

control over safety risks, and a good reputation in the importing

countries. Such enterprises are granted favorable policy treatment.

Enterprises with serious quality problems as reported by the

importing countries or regions, or which have avoided inspection

and quarantine or cheated the inspection and quarantine authorities

are punished in accordance with the law and included in the List of

Unlawful Enterprises and publicized on the Internet so as to

enhance the self-disciplinary awareness of enterprises producing

export food. So far, 55 enterprises have been put on the list.

Over the years, the departments of quality supervision and

inspection, trade, customs, industry and commerce, and taxation

have worked closely to promote the quality and safety level of food

exported from China and satisfy numerous Chinese and foreign

customers with high-quality, delicious and inexpensive foodstuffs.

Yet, there are still a tiny number of enterprises that disregard

the law, regulations and standards of China and importing countries

and, by deception or fraud, avoid supervision by the inspection and

quarantine authorities, or export food by improper channels.

Consequently, some adulterated, counterfeit or shoddy foodstuffs

have found their way from China into foreign markets. The Chinese

government is determined to step up the fight against such

activities and prevent substandard foodstuffs from going

overseas.

IV. Law Regime and Technological

Guarantee System for Food Safety

1. Food Safety Law Regime Gradually Improved

China now has a complete law regime providing a sound foundation

and good environment for guaranteeing food safety, improving food

quality and regulating food imports and exports.

The specific laws in this regard include the Product Quality

Law, Standardization Law, Metrology Law, Law on the Protection of

Consumer Rights and Interests, Law on the Quality and Safety of

Agricultural Products, Criminal Law, Food Hygiene Law, Law on

Import and Export Commodity Inspection, Law on Animal and Plant

Entry and Exit Quarantine, Frontier Health and Quarantine Law and

Law on Animal Disease Prevention.

The specific administrative regulations in this regard include

the Special Regulations of the State Council on Strengthening

Safety Supervision and Administration of Food and Other Products,

Regulations of the People's Republic of China on the Administration

of Production Licenses for Industrial Products, Regulations of the

People's Republic of China on Certification and Accreditation,

Regulations for the Implementation of the Law of the People's

Republic of China on Import and Export Commodity Inspection,

Regulations for the Implementation of the Law of the People's

Republic of China on Animal and Plant Entry and Exit Quarantine,

Administrative Regulations of the People's Republic of China on

Veterinary Medicine, Administrative Regulations of the People's

Republic of China on Pesticides, Provisions of the People's

Republic of China on Place of Origin of Export Goods, Regulations

for the Implementation of the Standardization Law of the People's

Republic of China, Measures for Investigating, Punishing and

Banning Unlicensed Business Operations, Regulations on the

Administration of Feedstuffs and Feed Additives, Administrative

Regulations on the Safety of Genetically Modified Agricultural

Organisms and Regulations of the People's Republic of China on

Import and Export of Endangered Wild Fauna and Flora.

The specific departmental rules include the Detailed Rules for

the Implementation of the Measures for the Administration of the

Supervision of Quality and Safety of Food of Food Producing and

Processing Enterprises (Trial), Measures for the Implementation of

the Regulations of the People's Republic of China for the

Administration of Production Licenses for Industrial Products,

Measures for the Administration of Food Hygiene Licenses, Measures

for the Hygiene Administration of Food Additives, Measures for the

Administration of Inspection and Quarantine of Entry and Exit Meat

Products, Measures for the Administration of Inspection and

Quarantine of Entry and Exit of Aquatic Products, Measures for the

Administration of Food Safety in the Circulation Sector, Measures

for the Administration of the Safety of Places of Origin of

Agricultural Products, Measures for the Administration of the

Packaging and Marks of Agricultural Products and Regulations for

the Administration of Hygiene Registration of Export Food

Production Enterprises.

2. Construction of Food Quality and Safety Standard System

Gradually Strengthened

The Standardization Administration of the People's Republic of

China administers the country's food standardization work, while

relevant departments under the State Council are in charge of

specific food standardization work in respective sectors. The

departments concerned are responsible for drafting different

national standards for food safety, while the Standardization

Administration initiates projects, examines them, marks the serial

numbers, gives formal approval and promulgates them. Now, a food

quality and safety standard system covering all categories,

featuring a relatively rational structure and being fairly

complete, has taken initial shape in China. Food safety standards

cover the place of origin of agricultural products, quality of

irrigation water, rules for the rational use of materials put into

agriculture, rules and procedures for animal and plant quarantine,

good agricultural practices (GAP), standards of maximum amount of

pesticides, veterinary drugs, pollutants and spoilage organisms

allowed in food, standards for food additives and their use,

hygiene standards for food packaging materials, standards for

special dietary food, standards for signs or labels on food

packages, standards for the management and control of the safe

production of food and standards for testing methods concerning

food. These standards apply to edible agricultural products and

processed food, such as grain, oil, fruit and vegetable, milk and

dairy products, meat, poultry, eggs and related products, aquatic

products, soft and alcoholic drinks, condiments and infant food;

and cover each sector from food production, processing and

distribution to final consumption. So far, China has promulgated

over 1,800 national standards concerning food safety, and over

2,900 standards for the food industry, among which 634 national

standards are compulsory.

To solve such problems as food safety standards overlapping each

other and poorly organized, China has sorted out the over 1,800

national standards, over 2,500 industrial standards, over 7,000

local standards and over 140,000 enterprise standards, repealing

more than 530 national and industrial standards. Meanwhile, it has

speeded up the revision of over 2,460 national and industrial

standards, issued over 200 new national standards, and worked out

plans to enact over 280 national standards. It also works hard to

promote and enforce these standards, and urges food producing

enterprises to strictly abide by them.

3. Food Certification and Accreditation System Basically

Established

The Certification and Accreditation Administration of the

People's Republic of China is responsible for administering,

supervising and coordinating certification and accreditation work

throughout the country, putting in order the certification market

and regulating certification activities. A pattern of uniform

administration, standardized operation and common implementation

for the certification and accreditation of food and agricultural

products has come into being, basically establishing a

certification and accreditation system covering the entire process

"from the farming field to dining table." The certification

categories include certification of feeds, GAP certification,

certification of hazard-free agricultural products, certification

of organic products, certification of food quality, certification

of the HACCP management system, and certification of green markets.

At present, China ranks among the top ten countries in the world in

this regard, with 2.03 million hectares producing certificated

organic products. The country has been experimenting with GAP

certification geared to international standards in 286 export

enterprises and agricultural standardization demonstration bases in

18 pilot provinces; 2,675 food producing enterprises have received

HACCP certificates; 28,600 primary agricultural products have

passed the certification tests for hazard-free agricultural

products; and continuous progress is being made in the

certification of feeds, alcoholic beverages by quality grade, and

green markets. The government continuously strengthens its

supervision of certificated products and enterprises, and increases

the authoritativeness and effectiveness of certification.

4. Food Safety Inspection and Testing Framework Taken

Initial Shape

Regarding the supervision of foodstuffs for the domestic market,

China has established a number of qualified food inspection and

testing institutions, bringing into initial being a food safety

inspection and testing framework with "state-level inspection

institutions playing the leading role, provincial- and

ministerial-level food inspection institutions forming the main

body, and city- and county-level food inspection institutions

acting as supplement." With the improvement of their testing

capability and level, these institutions can satisfy the demands

for quality and safety tests throughout the entire process -- from

the environment of place of origin, input materials, production and

processing, storage and circulation to consumption, and can

basically meet the requirements of national, industrial and

relevant international standards for food safety parameters. China

adopts the certification management that is in line with the

international practice for food laboratories, and strengthens

international mutual recognition, information sharing and joint

tackling of key scientific and technological problems, ensuring the

accuracy and fairness of test results. China has accredited the

qualifications of some food inspection and testing institutions.

Altogether, 3,913 food testing laboratories have passed the

laboratory accreditation (similar to metrology certification) of

China National Accreditation Service for Conformity Assessment

(CNAS) among which 48 are state-level quality inspection centers

for foodstuffs and 35 are key food laboratories. The testing

capability and level of these laboratories have reached a

relatively advanced international standard. As regards the

supervision of import and export foodstuffs, a technical support

system ensuring food safety has taken shape, with the 35

state-level key laboratories playing the leading role. There are

163 inspection and quarantine laboratories for import and export

foodstuffs throughout China, possessing more than 10,000 sets of

large precision instruments of various types. Altogether, 1,189

professionals are directly engaged in the laboratory testing of

import and export foodstuffs in these laboratories, with a rational

age structure and allocation of staff according to their

specialized fields. These laboratories can detect all kinds of

food-borne pathogens and 786 safety or hygienic items, such as

residue of pesticides and veterinary medicines, additives and heavy

metals. By 2006, China had set up 323 state- and ministerial-level

quality inspection centers and 1,780 provincial-, prefecture- and

county-level testing institutions concerned with agricultural

products. Thus, a quality and safety inspection and testing

framework for agricultural products, with these institutions at

different levels supplementing each other, has taken shape,

providing technical support for strengthening the supervision of

the quality and safety of agricultural products.

V. International Exchanges and

Cooperation Regarding Food Safety

The Chinese government sets great store by cooperating with

other countries, regions and international organizations regarding

food safety, as well as by learning advanced management expertise

and monitoring technology, to improve the overall quality of its

foodstuffs.

1. Strengthening Exchanges and Cooperation Regarding

Food Safety Technology

China encourages and supports its technical experts to

participate in various food safety technological training programs,

seminars, exchanges and comparative reviews. It also welcomes

overseas experts to visit China for study or training. Besides the

activities organized by the World Health Organization (WHO), China

has, since 2001, conducted many rounds of technological training

and exchanges on food safety, especially the implementation of the

Agreement on the Application of Sanitary and Phytosanitary Measures

(SPS), with the US, the EU, Italy, Canada, Germany, the UK,

Switzerland, Denmark, Australia, New Zealand and Thailand. In

August 2006, China sponsored food safety training for people from

14 South Pacific countries. To furnish itself with timely

information to ensure the foodstuffs it exports are up to the

relevant standards, China has translated the laws on food safety

and hygiene of the US, the EU, Russia, the ROK and other countries

and regions. It has also invited experts from the US, the EU and

Japan to offer training on HACCP application, the National

Shellfish Sanitation Program (NSSP), residue control and Positive

List System. China's laboratories for import and export food

inspection and quarantine have taken part in several comparative

experiments, such as the Food Analysis Performance Assessment

Scheme (FAPAS) of the UK, and joined on regular intervals the

international proficiency testing conducted by established

certification agencies, such as the Asia Pacific Laboratory

Accreditation Cooperation (APLAC) and the Australia's National

Association of Testing Authorities (NATA). The national center for

disease control and prevention and a dozen provincial ones have

passed the WHO food safety inspection capacity verifications. By

November 2006, a total of 22 inspection agencies had been granted

by the ROK to be "Acknowledged Overseas Official Inspection

Agencies," which means that the food items that pass their checks

will be free from entry inspection in that country. The testing

results of the laboratories of the 35 quality inspection and

quarantine agencies directly under the General Administration of

Quality Supervision, Inspection and Quarantine have also won

acknowledgement from Japan, and many of the laboratories are open

ones and have hosted delegations of experts from the US, Canada,

the UK, France, Italy, Germany, Switzerland, Australia, New

Zealand, Japan, the ROK, Singapore, Hong Kong, as well as other

countries and regions.

2. Actively Participating in International Activities

Regarding Food Safety

The Chinese government has always been a keen advocator of and

participant in international food safety activities. It has

dispatched delegations to the Codex Alimentarius Commission (CAC),

the International Plant Protection Convention (IPPC) and other

international conferences. Its call for regional cooperation on

food safety at a meeting of the Asia-Pacific Economic Cooperation

(APEC) has received positive responses from Australia, New Zealand

and Southeast Asian countries, as a result of which the APEC Food

Safety Cooperation Forum was established, co-chaired by China and

Australia. China actively participates in international

standardization activities for food safety. It is a member of the

Technical Management Board and Committee on Conformity Assessment

of International Organization for Standardization (ISO). In May

2007, it formally joined the World Organization for Animal Health

(OIE). On October 20-21, 2007, it will host, in Nanning, the

China-ASEAN Ministerial Conference on Quality Supervision,

Inspection and Quarantine, with the theme of "Strengthening

Cooperation on Food Safety Management and Protecting Consumer's

Rights." The event will discuss the establishment of a cooperative

mechanism on food safety, so as to increase exchanges and

cooperation among the relevant departments of China and ASEAN to

ensure the quality, safety and sanitation of the foods traded among

them.

3. Striving to Promote International Cooperation

Regarding Food Safety

While organizing regular and irregular seminars or mutual visits

of experts with Japan, the ROK, Australia, New Zealand, Singapore,

Norway, Russia, Hong Kong, and other countries and regions, China's

General Administration of Quality Supervision, Inspection and

Quarantine has signed 33 cooperative agreements or memorandums on

food safety and 48 import and export food inspection and quarantine

protocols with 30 countries and regions, namely the US, the EU,

Russia, Japan, the ROK, Singapore, Thailand, Mongolia, Vietnam, the

Philippines, Denmark, France, the Netherlands, Ireland, Hungary,

Poland, Italy, Norway, Switzerland, Canada, Brazil, Argentina,

Chile, Mexico, Uruguay, Australia, New Zealand, South Africa, Hong

Kong and Macao. Thus, a long-term and effective cooperative

mechanism between China and its food trade partners has been

established. And, based on this, the General Administration of

Quality Supervision, Inspection and Quarantine has built a system

of annual meetings with many countries and regions. The second

China-EU meeting on safety of food and consumer products at the

ministerial level is scheduled to be held on September 12, 2007 in

Beijing, and the third China-US food safety meeting at the

vice-ministerial level is scheduled on September 11-12, 2007 in the

US.

4. Promoting Food Trade

The food safety cooperative mechanisms established between China

and other countries have greatly promoted bilateral and

multilateral cooperation to ensure the safety of foodstuffs traded

among them and ease the wide concerns about food safety. For

instance, the Sino-Japanese cooperative mechanism plays a key role

in ensuring the safety of Chinese food exported to Japan. After

Japan's release of its Positive List System, the Chinese

government, through communications and negotiations, persuaded

Japan to accept its reasonable proposals and adjust some projects

accordingly, and co-sponsored three demonstrations and eight

special training workshops to help China's food export enterprises

further standardize the use and administration of pesticide and

veterinary medicines, improve the quality tracing system and

guarantee the quality and safety of food exported to Japan. The

China-US food safety cooperative mechanism plays a similar role.

Since the end of 2005, China's entry-exit inspection and quarantine

authorities have continuously found residues of prohibited

medicines, pollutants and pathogenic microbes in US meat products

exported to China. Their timely notification of such information

let the US learn of China's legal requirements concerning food

safety, thus effectively protecting Chinese consumers as well as

ensuring healthy development of US export of meat products to

China. In 2004 and 2005, the two countries, under this cooperative

mechanism, evaluated the safety and sanitation of China's exported

cooked poultry products. The China-EU food safety cooperative

mechanism also works well in solving problems both sides are

concerned about. Through timely communication and on the basis of

risk assessment, China has solved problems in the import of pork

products from some dioxin-affected EU countries. While continuously

improving its own food safety management and epidemic prevention

and control work, it has actively cooperated with the EU in

undertaking hygienic system inspection and risk appraisal which

helps build confidence in China's cooked poultry products. The EU

has worked out a timetable to resume imports of China's cooked

poultry products in 2007.

Food is the first necessity of man, and it is the most direct

and most important consumption product of mankind. China is a

responsible country, and the Chinese government is devoted to

working for the benefits of the people. Over the years, the Chinese

government has endeavored to improve food quality, ensure food

safety and protect consumers around the world. But, it must be

pointed out that China is still a developing country, and the

overall level of food safety, including the standards and the

industrialization level of food production, still lags behind that

of developed countries. China has a long way to go to improve the

quality of foodstuffs. Food quality and safety is a common concern

of the human society and a shared duty of the international

community. As a large importer and exporter of food, China is keen

to strengthen exchanges and cooperation with other countries and

make unremitting efforts to ensure the safety of food and promote

the healthy growth of the global food trade.

(China.org.cn August 17, 2007)