Catching up fast in 3D printing

0 Comment(s)

0 Comment(s) Print

Print E-mail China Daily, July 25, 2016

E-mail China Daily, July 25, 2016

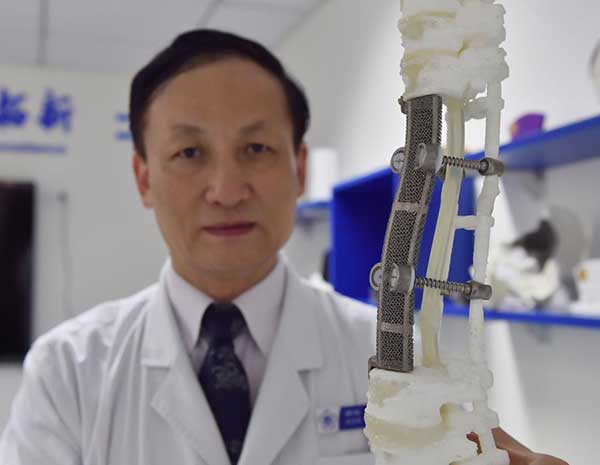

A patient suffering from a malignant tumor recently received unconventional, almost science fiction-like yet real and successful treatment. His doctor replaced five affected segments of his spine with a 19-centimeter-long metal part that was created using a 3D printer.

Doctor Liu Zhongjun performed the surgery a month ago in Peking University Third Hospital.

"We used to use titanium mesh stuffed with crushed bones from the patient or other bodies to replace the spines. However, this method was far from ideal, because if the titanium mesh changed position, the patient would be paralyzed, and the column-shaped mesh didn't match the S-shaped biological curve of human beings," said Liu, head of the 3D printing artificial vertebral body research team, which is recognized by the China Food and Drug Administration.

The 3D printing technology has enabled surgeons to custom-make replacements for spine. The flexible metal spine is said to readily connect to other bones and form a stable link, supporting the body. With it in place, a patient can move freely soon after the operation, and can live and work like a normal person, according to Liu.

Welcome to the fascinating world of 3D printing. Theoretically, a 3D printer can 'print' or create anything drawn on paper into a three-dimensional object.

The technology is formally called additive layer manufacturing by researchers and scientists. In the past few years, 3D printing has surprised many by creating things from clothing to homes to machine parts to even drones.

Chuck Hull, an inventor from the United States, developed solid imaging back in 1980s. The process is different from traditional manufacturing. The latter is based on the removal of material by cutting and drilling. But 3D printing creates objects by consistently laying down materials, such as wax, metal and polyurethane, based on virtual blueprints from computer-aided designs.

"The main advantages of 3D printing over traditional manufacturing include reduced manufacturing cost, shorter production and delivery times, and the ability to produce complex shapes that are difficult to create using traditional methods," said Donald Godfrey, engineering fellow at Honeywell Aerospace.

According to Godfrey, in terms of shorter turnaround times, 3D printing technology can help shave months off delivery schedules. Some products can even be produced in less than a day, which will have a major, positive impact on customers.

"In the early stage of its development, 3D printing could only produce low-intensity goods, so it was called Rapid Prototyping Manufacturing. In 1991, Yan Yongnian, a professor at Tsinghua University, invited professor Jack Keverian from the US to introduce 3D printing technology to China. Since then, China embarked on the journey of researching and developing 3D printing," said Lin Feng, a professor at the university's mechanical and engineering department.

According to Lin, the Tsinghua University team designed a 3D printer in early 1990s and the first product of the printer was a car model made from paper.

"We did not start much later than our counterparts globally, and our researchers and experts are striving to catch up in the application of this technology in more areas with a broad selection of materials," said Zeng Xiaoyan, a professor from the Huazhong University of Science and Technology.

Go to Forum >>0 Comment(s)