'Core tech needed' for robotics

0 Comment(s)

0 Comment(s) Print

Print E-mail China Daily, October 22, 2016

E-mail China Daily, October 22, 2016

|

|

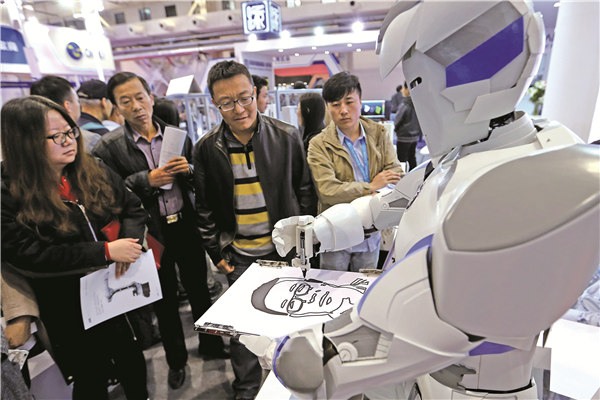

| A robot draws a portrait at an industry expo held in Beijing on Friday. [Photo / China Daily] |

Long-term commitments to core technologies and closer ties with artificial intelligence firms are needed to make robots more intelligent and flexible, as China ramps up resources to upgrade its labor-intensive manufacturing with technological innovation, experts said on Friday.

Zhao Jie, a mechanic professor at Harbin Institute of Technology, a top engineering university in China, said China's robot industry is growing rapidly, but it is still bottlenecked by domestic robot maker's lack of competence to mass-produce reliable key robot parts.such as speed reducers.

"Most of components are still imported from foreign countries, which increases the cost of robots," Zhao said at a robot conference in Beijing.

Also, lack of well-known brands is limiting the development of the domestic robot sector, he added.

China became the world's biggest market for industrial robots in 2013, surpassing Japan, according to the International Federation of Robotics. But for every 10,000 employees, there are still only 36 robots in China, compared with 478 in South Korea, 292 in Germany and 164 in the United States in 2014.

Amid surging labor costs, the robotics federation estimates that China will likely to usher in more than one-third of the industrial robots installed worldwide in 2018, more than doubling over the next two years from 262, 900 currently to 614,200.

Michael Wang, professor of mechanical and aerospace engineering at Hong Kong University of Science and Technology, said that with advances in technology, robots would become increasingly affordable and what really mattered was how to expand various application scenarios.

"Currently, most robotic arms are deployed in the automotive industry, whose products are highly standardized," Wang said.

"But when it comes to the consumer electronics sector, robots are still not smart enough to assemble smartphones, which require the flexibility of human hands. That is the direction robot makers should move forward."

China earlier this year unveiled plans to triple its annual output of industrial robots to 100,000 in five years, which prompted investors to pour money into the booming industry.

Heavyweights such as Siasun Robot & Automation Co — China's largest robot maker by market value — and startups are all joining in.

Li Boji, deputy chief engineer at GSK CNC Equipment Co Ltd, a major robot maker in China, said the robot industry was more complicated than the smartphone sector, with far more components and technologies involved. "Any breakthrough demands long-term efforts. Shortsighted strategies will lead to failure," Li said.

Zhao, from Harbin Institute of Technology, agreed. "The robot industry is investment-intensive, highly risky and of slow-return," he said.

"Investors need to remain calm and have a clear mind. More efforts are needed to focus on scientific research."

Go to Forum >>0 Comment(s)